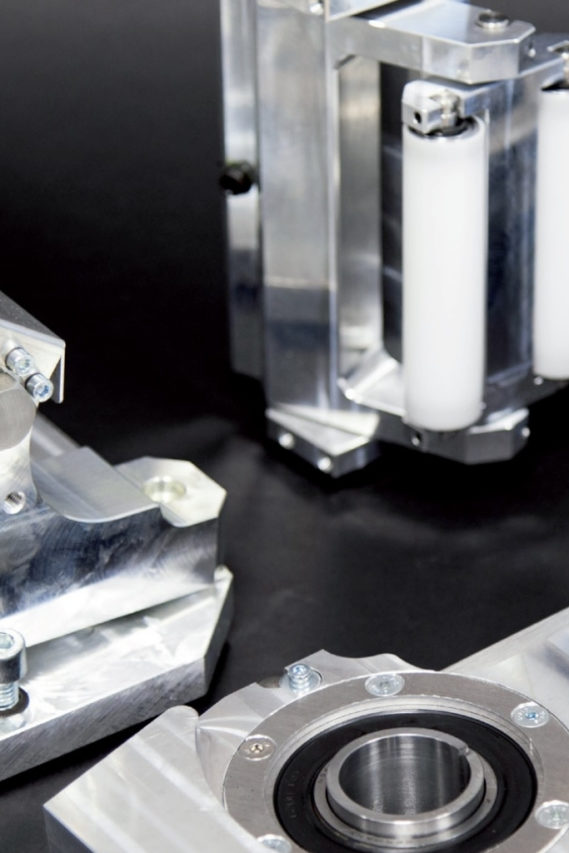

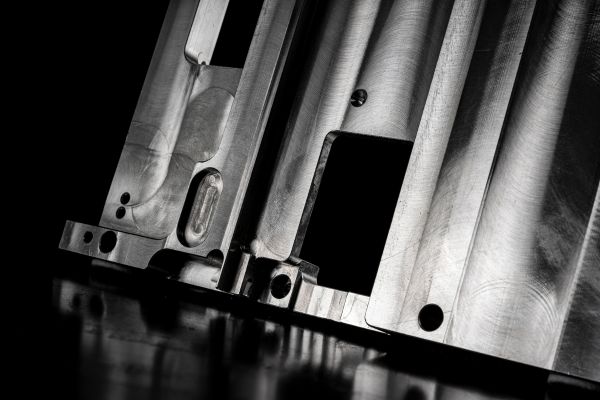

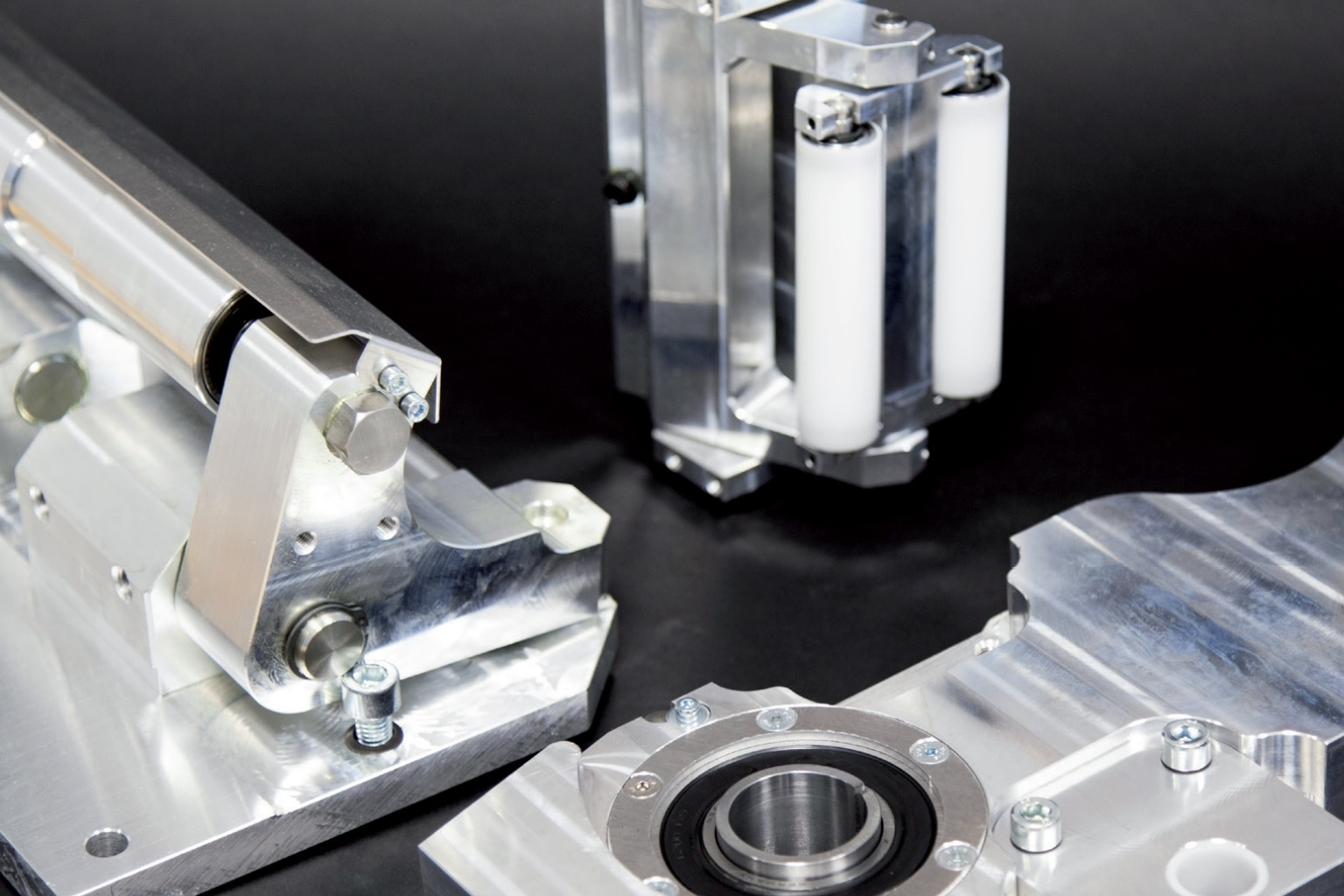

Macchine di ultima generazione, personale altamente qualificato e una struttura produttiva costantemente aggiornata. Realizziamo lavorazioni meccaniche di precisione dall’ingegnerizzazione del modello all’industrializzazione del prodotto in 10 settori industriali differenti per il mercato italiano ed estero adattandoci a ogni richiesta di lotti produttivi.

Macchine di ultima generazione, personale altamente qualificato e una struttura produttiva costantemente aggiornata. Realizziamo lavorazioni meccaniche di precisione dall’ingegnerizzazione del modello all’industrializzazione del prodotto in 10 settori industriali differenti per il mercato italiano ed estero adattandoci a ogni richiesta di lotti produttivi.

USTER

Make precision

Cura del dettaglio, innovazione del prodotto.

del processo di produzione

incisioni al laser di altissima precisione

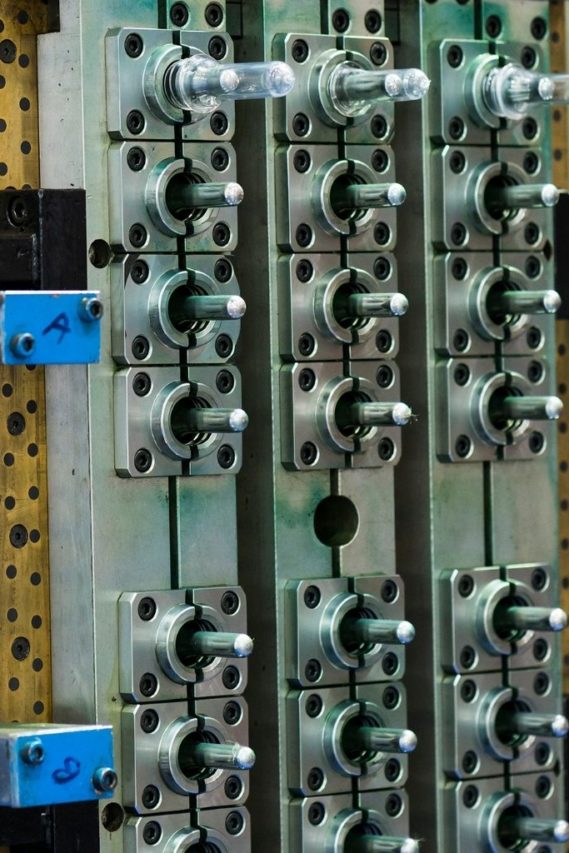

LA PRODUZIONE

Il modello di prototipo o la campionatura nasce su progetto del Cliente. Prima di iniziare con la realizzazione del prodotto vengono effettuate precise valutazioni e minuziose verifiche.

CONTROLLI DIMENSIONALI

ASSEMBLAGGIO E COLLAUDO

grazie a procedure interne e personale qualificato che ci permette di rispettare tempi e indicazioni dell'ordine.

INDUSTRIALI

PRODOTTI

DI ATTIVITA'

Riservatezza

Fai precisione con Uster

Uster Srl è beneficiaria di un contributo sul Bando POR FESR 2014-2020. ASSE 1 Azione 1.1.2 " Sostegno per l’acquisto di servizi per l’innovazione tecnologica, strategica, organizzativa e commerciale delle imprese" da parte della Regione Veneto, con un progetto dal titolo INNOVAZIONE ORGANIZZATIVA. Il progetto è stato finalizzato ad introdurre un'innovazione organizzativa principalmente nei processi strategici di direzione e controllo, gestione risorse umane, commerciale, marketing e produttivo.

Obiettivi principali del progetto:

- implementazione nuovo strumento di controllo della gestione e della produttività;

- Incremento delle azioni di innovazione;

- Incremento della competitività aziendale.

Il progetto è stato approvato con una spesa ammessa di € 50.000,00 e ci è stato concesso un contributo di € 15.000,00.

Bando POR FESR 2014-2020 - ASSE 3 AZIONE 3.4.2

Titolo del progetto: PIANIFICAZIONE STRATEGICA PER LO SVILUPPO INTERNAZIONALE DI USTER SRL

Il progetto è stato finalizzato ad acquisire un servizio di consulenza di pianificazione strategica finalizzato alla penetrazione nei mercati internazionali prescelti. In particolare, il servizio ha previsto l'elaborazione di un piano strategico di internazionalizzazione per la creazione e lo sviluppo di specifiche reti commerciali nei mercati target. Il progetto è risultato coerente con il servizio B1 previsto dal bando per il sostegno all'acquisto di servizi per l'internazionalizzazione da parte delle PMI.

Il progetto è stato approvato con una spesa ammessa di € 29.400,00 con contributo di € 11.760,00.