Production department

PRODUCTION

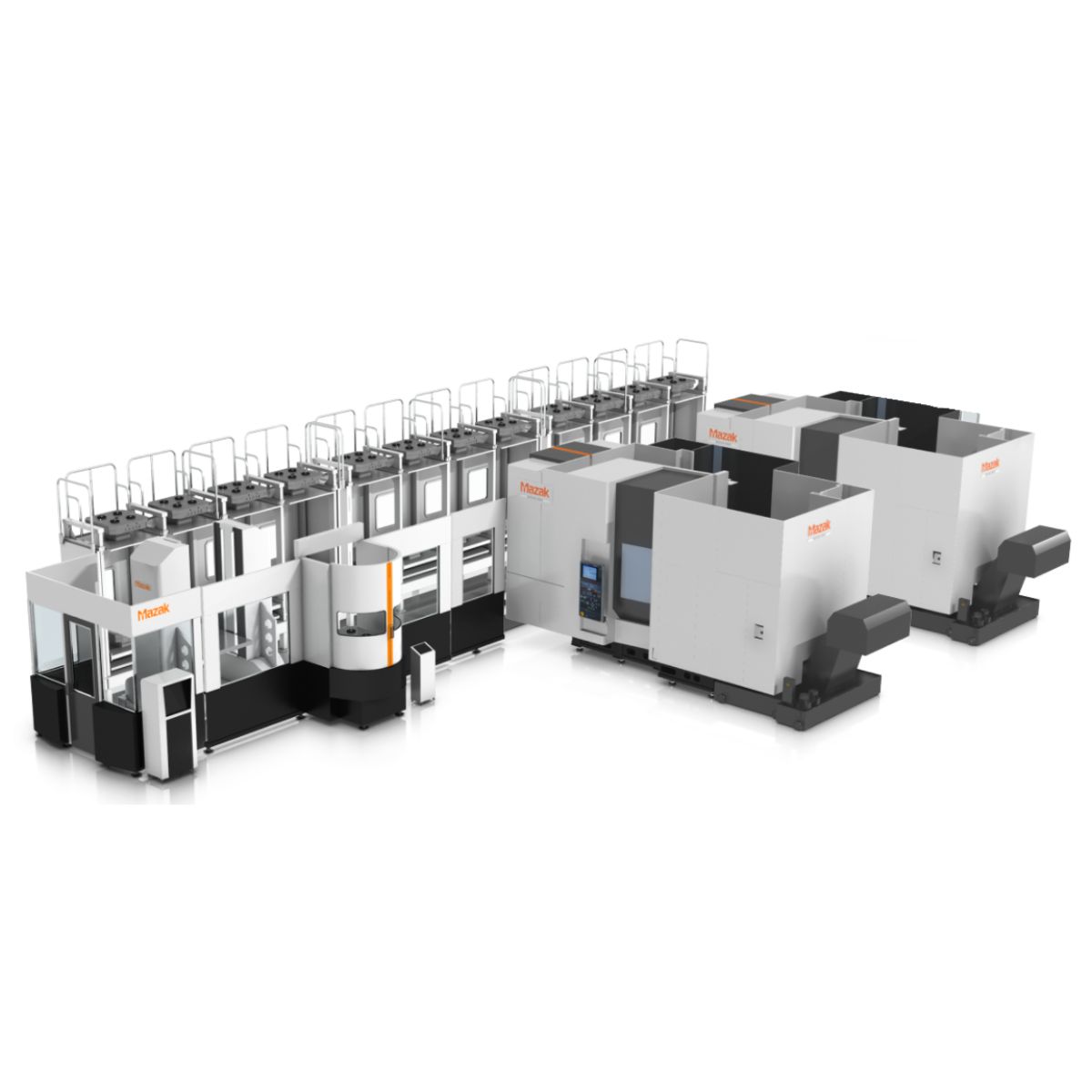

A technologically advanced machine fleet with periodic checks and maintenance.

With the 5-axis multitasking systems we produce components with a single machine placement from raw material to the finished part. This technology allows to obtain details with the greatest accuracy both dimensional and geometric.

In this department we have Mazak Integrex and Mazak Variaxis to ensure the production of even the most complex items.

With the 5-axis multitasking systems we produce components with a single machine placement from raw material to the finished part. This technology allows to obtain details with the greatest accuracy both dimensional and geometric.

In this department we have Mazak Integrex and Mazak Variaxis to ensure the production of even the most complex items.

MACHINE PARK

Milling and automation

4 Horizontal machining centers MAZAK HCN5000-II

730x730x500 - 18,000 RPM - 120/180 machine toolsFMS MAZAK 26 palletech station line

2 MAZAK HCN5000-II horizontal machining centers

730x730x500 - 18,000 RPM - 80/120 machine toolsFMS MAZAK 16 station palletech line

2 Mazak Variaxis 630-5X 5 axis machining centers

630x760x510 - 12,000 RPM - 80 machine toolsFMS MAZAK Palletech line of 30 stations

MULTITASKING DEPARTMENT 5 AXES

MAZAK Integrex i-200SGL-V

Max diam. 200 - 12,000 RPM - 110 tools - Portal robotMAZAK Integrex i-200S-IV

Max diam. 200 - 12,000 RPM - 74 tools - Anthropomorphic robotMAZAK Integrex i-200-V

Max diam. 200 - 12,000 RPM - 74 toolsMAZAK Integrex i-200-HS

Max diam. 200 - 12,000 RPM - 74 toolsTURNING

MAZAK SQT250

Max diam. 150MAZAK QT15

Max diam. 80EQUIPMENT

Milling machine INDUMA ISO 50

Milling machine NOVAR ISO 40

URSUS lathe

WASHING

Ultrasonic system DBM

MARKING

Laser marking machine KEYENCE

RMU dot marking machine

CONTROL ROOM

3D measuring machine Zeiss Contura

700x1000x600Altimeter Mitutoyo

Stroke Z600Pressure gauge Garant

Parameters in: Ra, Rz, Ry, Rt, Rp, Rq ...

MILLING DEPARTMENT

Also in the milling department we guarantee our customers production continuity thanks to the presence of horizontal machining centers with the same characteristics.

The 6th Mazak HCN-5000 Milling Plant further optimizes and improves its performance with the latest generation of Smooth Control.

The 6th Mazak HCN-5000 Milling Plant further optimizes and improves its performance with the latest generation of Smooth Control.

FMS LINES

Uster has 3 automated and integrated FMS lines with at least 20 workstations each. This type of solution offers great autonomy and continuity of production even in unmanned.

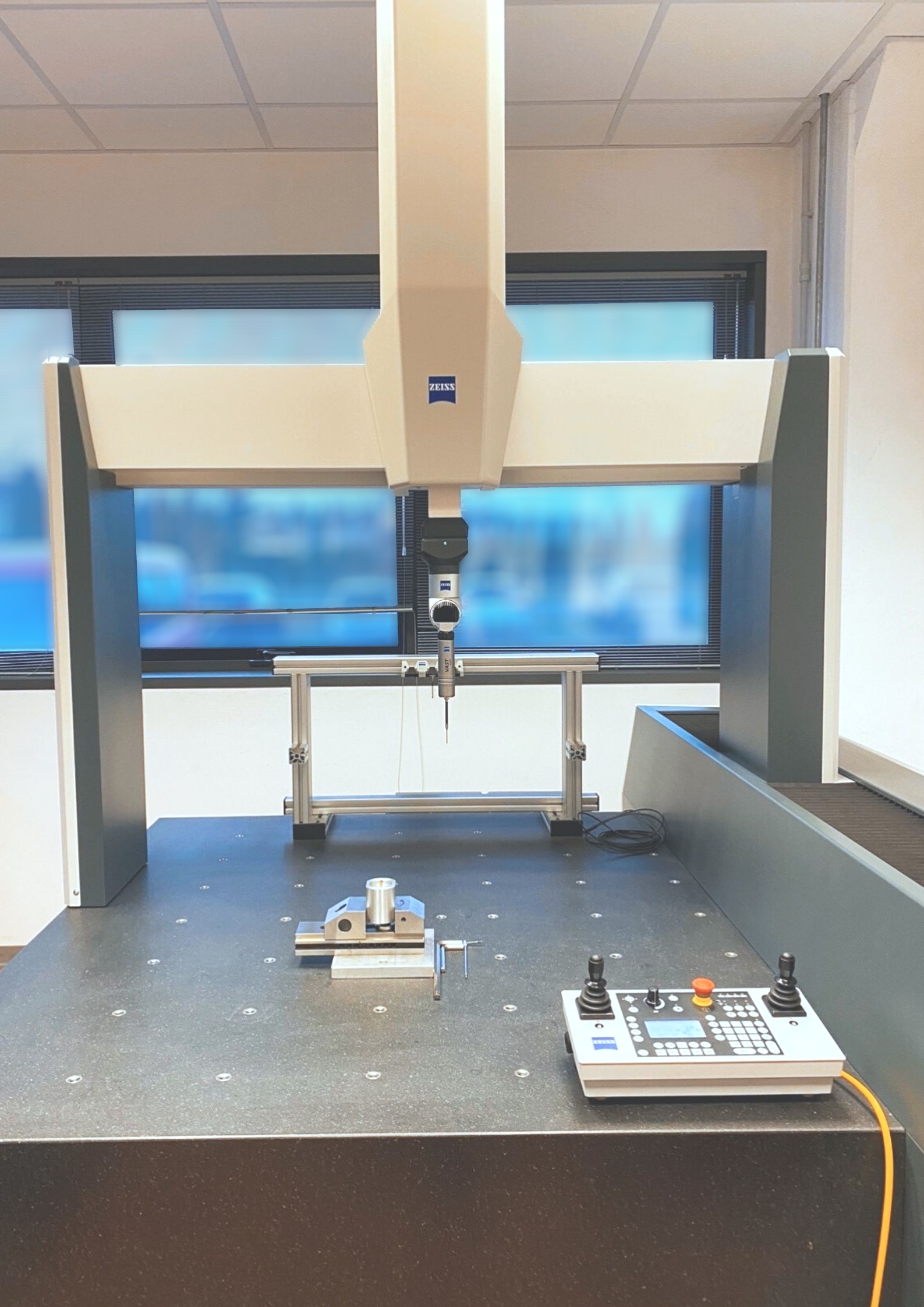

metrological room

In the metrology room, specific checks are carried out for DIMENSIONAL TESTING CERTIFICATES of mechanical components with the verification of dimensional and geometric specifications, of surface roughness on samples or entire productions, according to customer needs.

The metrology room is an air-conditioned control space realized according to the guidelines of the standards uni EN ISO 1:2003 and ISO /IEC 17025 with the most sophisticated measuring instruments.

More than 400 measuring instruments

There are various gauges, micrometers, comparators, reamers, smooth pads, threaded, rings, the roughness meter, two altimeters Mitutoyo and a hardometer that can guarantee the best performance in terms of quality and reliability of control.

In the metrology room, dimensional checks of mechanical components are carried out by verifying dimensional and geometric specifications on samples or entire productions according to customer needs.

The metrology room is an air-conditioned control space realized according to the guidelines of the standards uni EN ISO 1:2003 and ISO /IEC 17025 with the most sophisticated measuring instruments.

More than 400 measuring instruments

There are various gauges, micrometers, comparators, reamers, smooth pads, threaded, rings, the roughness meter, two altimeters Mitutoyo and a hardometer that can guarantee the best performance in terms of quality and reliability of control.

In the metrology room, dimensional checks of mechanical components are carried out by verifying dimensional and geometric specifications on samples or entire productions according to customer needs.

zeiss contura

The Zeiss "Contura" measuring machine guarantees the best performance in terms of quality and reliability of the control.

The measuring machine has been placed inside the air-conditioned metrology room in order to guarantee very high precision measurements thanks to a constant temperature and humidity.

Extra certificates: with Zeiss "Contura" we issue test certificates for assembled and quality groups for individual parts on customer request, further guarantee of the standard checks already provided in production.

Zeiss "Calypso": station for programming, model setting and simulator for measuring machine 3 D.

The measuring machine has been placed inside the air-conditioned metrology room in order to guarantee very high precision measurements thanks to a constant temperature and humidity.

Extra certificates: with Zeiss "Contura" we issue test certificates for assembled and quality groups for individual parts on customer request, further guarantee of the standard checks already provided in production.

Zeiss "Calypso": station for programming, model setting and simulator for measuring machine 3 D.